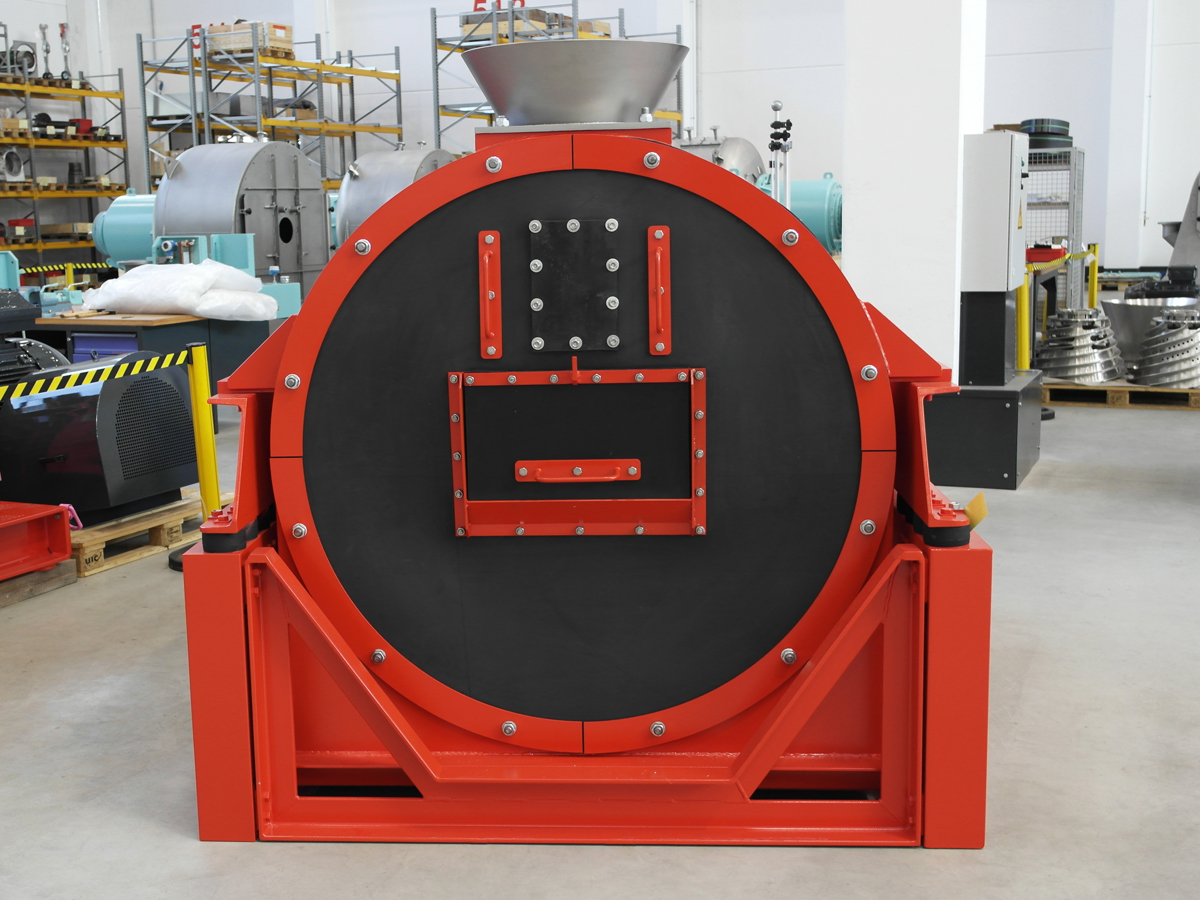

Vibratory Centrifuges

Vibratory Centrifuges / Vibrating Screen Centrifuges

Vibratory centrifuges from Siebtechnik Tema use eccentric weights to produce a uniform vibration behavior, resulting in less power consumption to save you money. The vibrating screen centrifuges offer more capacity thanks to adjustable axial vibrations and amplitude. The vibrations are generated by 2 counter-rotating imbalance weights.

This gives vibrations in the resonance range, slightly less than natural vibrations. The amplitude of the empty machine can be adjusted by setting the bias on the rubber buffers. As a result, the amplitude is automatically increased, which reduces downtime due to normal product shocks.

Vibrating screen centrifuges are most-suitable for processing mass products which can easily be dewatered to a relatively good final moisture. In regards the throughput of solids, the vibratory centrifuge is a highly-effective centrifuge.

Specifications by Model:

| Type & Model | HSG1100 | HSG1200 | HSG1300 | HSG1400 | HSG1500 |

| Feed capacity * t/h | 80-200 | 100-240 | 150-350 | 200-400 | 250-500 |

| Drive motor kW | 22 | 37 | 55 | 55 | 55 |

| Length in cm | 244 | 244 | 292 | 292 | 292 |

| Width in cm | 188 | 188 | 224 | 226 | 226 |

| Height in cm | 178 | 178 | 203 | 206 | 206 |

| Weight in kg | 4.309 | 4.445 | 6.985 | 7.030 | 7.030 |

* The actual capacities depend on the specific material properties.

Advantages

Vibratory Centrifuges are used successfully for:

- Coal: Lignite, Fine coal, Stock coal, Coarse slurry, Middlings, Shale.

- Salt: Flotation tailings, Flotation concentrate, Potash solvent residue, KCL granular crystallisate, Salt of silicic acid, Sea salt.

- Sand: Concrete sand, Pumice sand, Ground limestone, Shell sand, Silica sand, Oresand.

- General: Wood shavings