Screen/Scroll Coal Centrifuges H900 / H1000

Siebtechnik Tema Screen / Worm coal centrifuges, H 900 / H 1000

State-of-the-art coal centrifuges designed and developed from decades of experience

The Screen / Worm coal centrifuges (Conturbex) from Siebtechnik Tema are designed for fine coal dewatering with considerably more capacity per energy unit than other competing models. The patented, worm design ensures less particle breakage, prevents balance issues through uniform material distribution and extends the life of the screen.

Siebtechnik Tema have developed this machine design into an extremely versatile screening centrifuge that is suitable for a wide variety of separation requirements.

Operational behaviour and mechanical characteristics

To dewater fine coal, the coal slurry is fed into the small inner diameter of the scroll feed cone, where it is distributed evenly through feed holes by centrifugal action into flighting channels between scroll and screen basket. The high gravitational force from the centrifugal action forces the liquid portion of the feed slurry to pass through the screen, while the formed solids cake bed is continuously rotated and swept outward. Final product is then discharged at the large outer diameter of the screen basket.

The capacity and dryness of the cake depends on the size range of the solids and their draining characteristics. Our engineers will assess your unique fine coal feed characteristics and offer advice on how to achieve lowest product moistures.

Components

Siebtechnik Tema Fine Coal Centrifuges all incorporate the following basic components:

- Base Assembly

The base assembly is comprised of the lower-base frame and upper base frame. The lower-base bolts to the floor, supports the oil pump tank assembly and supports the upper base frame (through vibration isolators). The upper base supports the gear housing, basket drive assembly, drive motor, belt guard assembly and discharge housing assembly.

- Discharge Housing

The discharge housing is a two-compartment housing, covering the screen basket and scroll assembly. It serves the purpose of collecting centrate liquid and product solids, discharging each from separate openings.

- Gear Housing

The gear housing contains and supports the reducer, main bearings, seals and bearing carriers. The reducer housing rotates in the main bearings, supporting the screen basket and scroll assembly. The gear housing additionally functions as an oil sump for the cooling oil, which returns to the pump and tank unit.

- Reducer Assembly

The SIEBTECHNIK TEMA gear reducer (cyclo gearbox) is designed to have a single input speed with two output speeds. The basket drive sheaf and screen basket assembly both bolt to the reducer housing, thus the screen basket is directly driven, rotating at the same speed as the basket drive sheaf. The differential cyclo-gear design allows the output shaft to rotate slightly faster than the reducer housing. This causes the differential in speed between the screen basket and the scroll assembly, i.e. the screw conveyor effect where the scroll continuously carries the solids from the screen basket. The reducer assembly is continuously pressure lubricated with medium weight non-foaming oil.

- Screen Basket and Scroll Assembly

The screen basket is wedged and bolted within the screen cage, where the cage is bolted to the back plate, which mounts to the reducer housing via a hydraulic fit. The scroll and hub assembly mount to the reducer output shaft by means of a tapered fit and a clamping plate. A special tool set is provided for removing the scroll for screen basket replacement.

- Torque Limiter

To provide mechanical protection for the reducer assembly, a torque limiting clutch is mounted to the reducer input shaft via a torque arm. A limit switch is provided to yield a signal when the overload clutch releases, due to product or mechanical overload. The electrical signal disables the drive motor to protect the gear reducer. The torque load that will cause the clutch to release is generally greater than the main drive motor maximum operating load. The clutch is manually reset.

- Lubrication System

The lubrication system consists of an oil pump with motor, filter, oil tank, pressure gauge, pressure switch, oil lines and rotary union mounted to the reducer input shaft. The reducer and bearing carrier plates have pre-sized oil passages for the oil distribution. The oil is pressure fed to the bearings and cyclo-gear system, returning by gravity through the gear housing oil sump to the oil tank.

- Drives

The main drive consists of the driven-sheaf, mounted to the reducer housing, a fixed motor sheaf and V-belts. The main drive motor is mounted on an adjustable motor base. The oil pump motor is mounted on the oil tank unit.

Technical Specification

Specifications of available coal centrifuges by model

| Model | H900 | H1000 | H1200 |

|---|---|---|---|

| Motor Rating (kW) | 55 | 75 | 75 |

| Length (mm) | 2400 | 2400 | 2550 |

| Width (mm) | 2400 | 2400 | 2300 |

| Height (mm) | 2000 | 2000 | 2060 |

| Approx. weight (kg) | 3600 | 3850 | 4800 |

| *All figures for indication only, subject to change without prior notice. |

* The actual capacities depend on the specific material

Service

Our reliable service enables optimum operation of your machines and systems. We offer energy optimisation, machine monitoring, an on-site maintenance and & repair service, OEM spare parts, damage cause analysis, maintenance & repair kits, stock inventory analysis, machine history management, personal technical consultation, training & workshops, 24 hr service, retrofitting & upgrades and used & loan machines.

Ask us, we’re there for you.

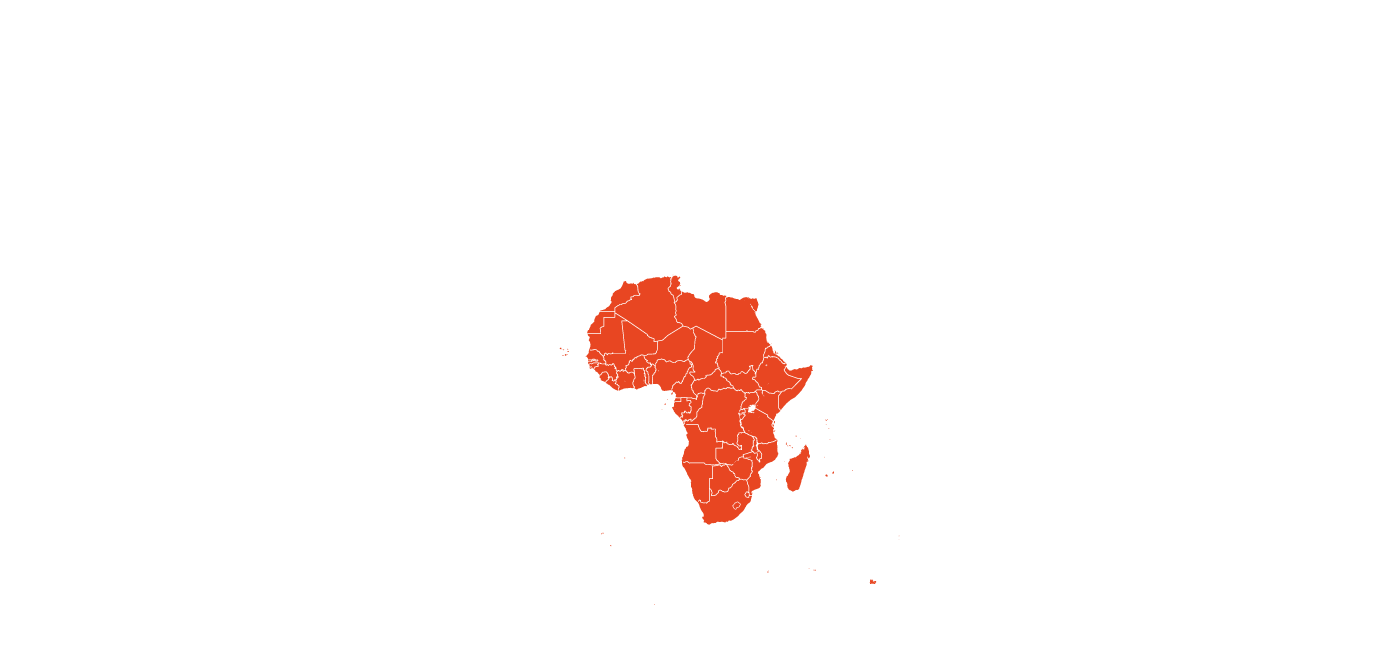

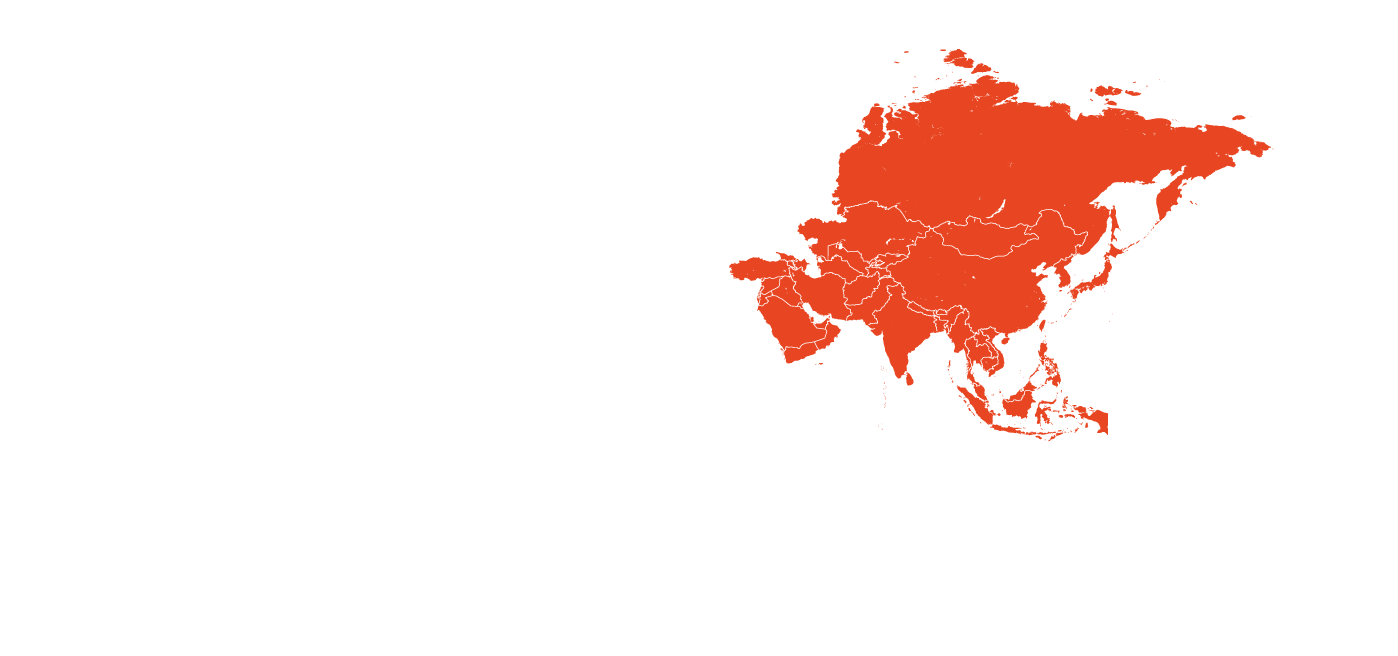

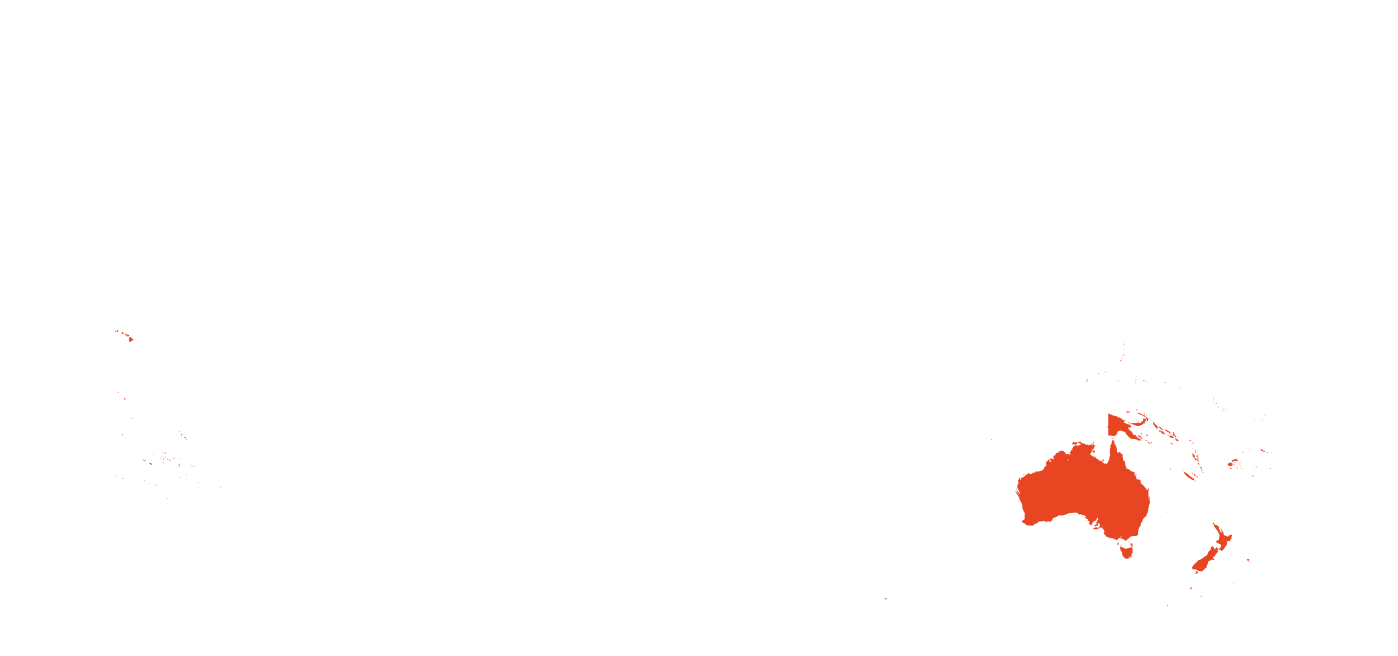

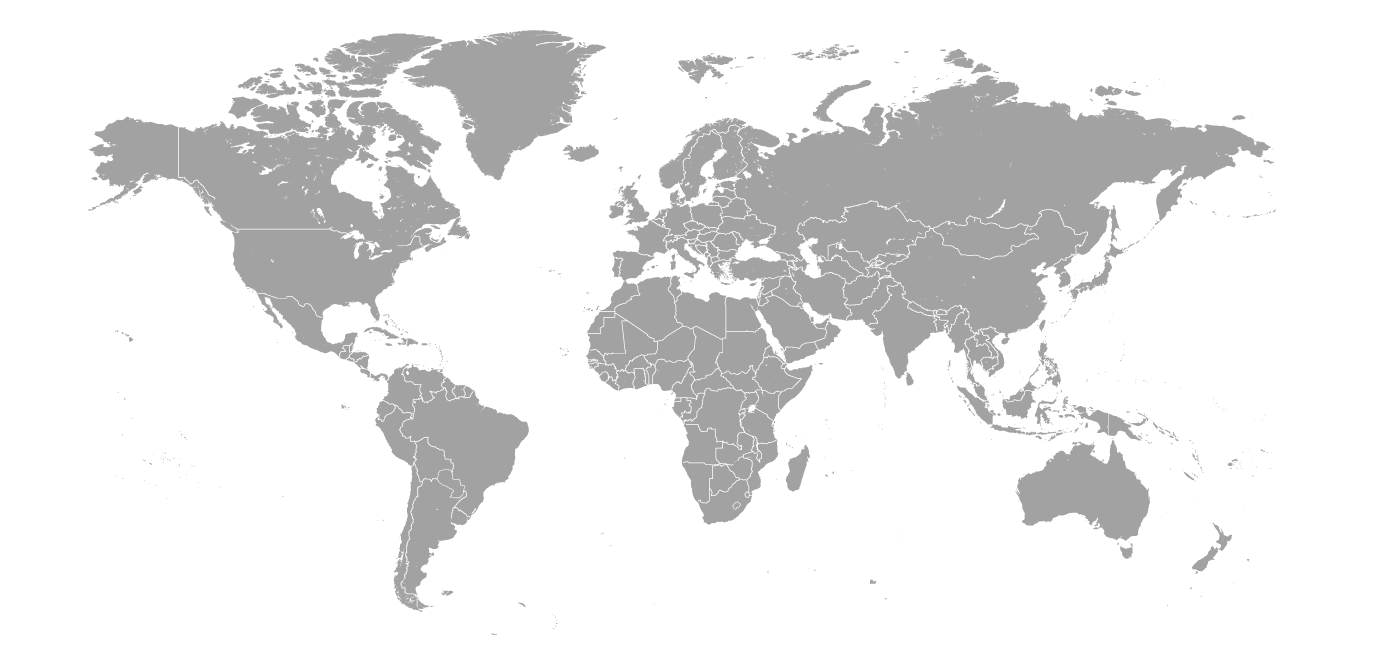

System Solutions

SIEBTECHNIK/TEMA has consistently developed itself into one of the world’s most innovative manufacturer of continuous centrifuges and suppliers of system solutions in the field of mechanical and thermal solid-liquid separation since the early 1940s. SIEBTECHNIK/TEMA is your reliable partner for customer-focused, custom-built machines and system solutions.

SIEBTECHNIK/TEMA centrifuge and drier systems offer you the latest technology, customer- and product-specific special fittings and individual consultation at the pre-sales stage and reliable support in the after-sales process. For mechanical liquid separation continuously operating centrifuges are often the technically and economically best solution. They separate large volumes in closed housings with little space requirement and low energy and time costs. Also drying on the fluidised bed with fluidised bed driers and coolers has established itself in numerous branches of industry and applications.

Advantages

Benefits of the H Series design

- High torque Sumitomo cyclo-gear drive

- Low maintenance

- Superior handling of shock loads caused by feed surge

- Lower ongoing costs

- Horizontal design means maintenance does not require total disassembly

- Requires no special foundation dampening

- Higher ‘G’ force design giving lower product discharge moisture

- Well proven design with over 650 machines operating worldwide