Sample taking & Sample preparation systems

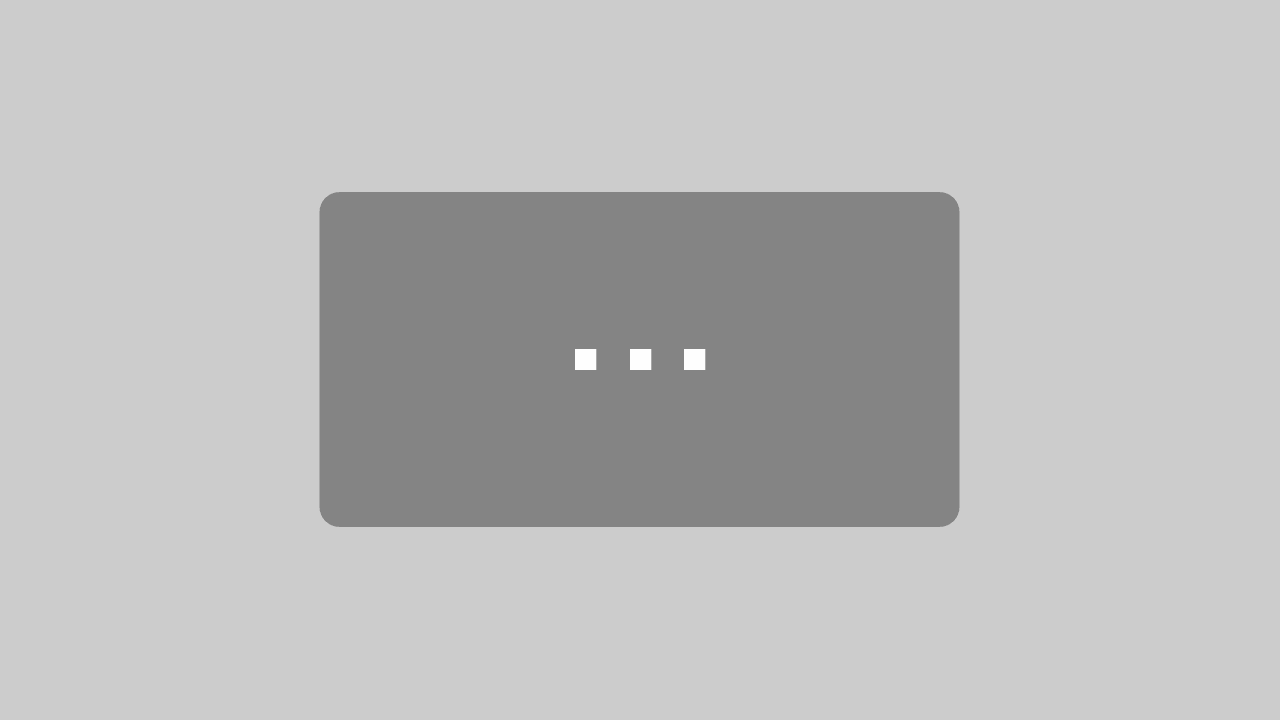

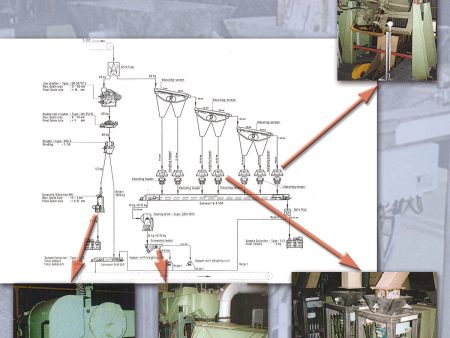

Sample taking & Sample preparation system

Continuously increasing demands on quality of raw materials and final products in industry ask for modern processing techniques and monitoring of product quality.

SIEBTECHNIK does not only have a wide-ranging product portfolio, but also a staff of employees with solid expert knowledge and worldwide and industry-specific experience.

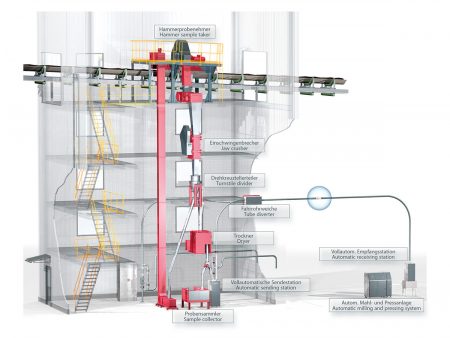

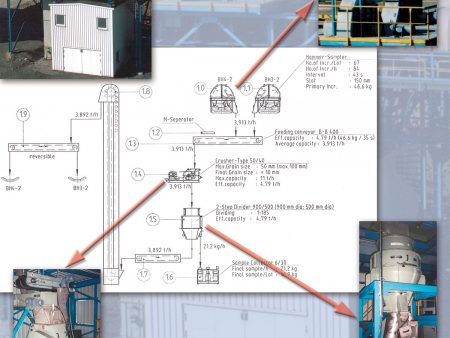

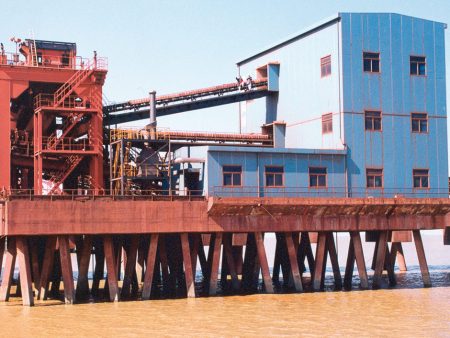

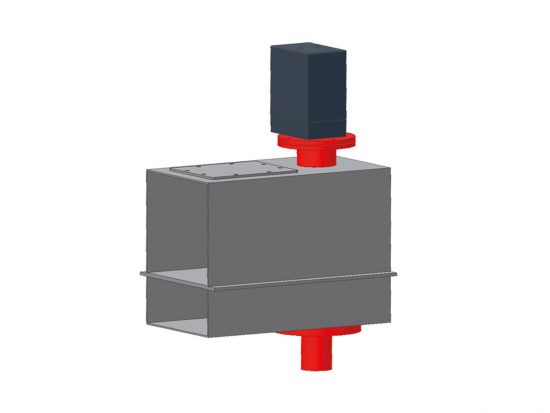

In the field of industrial sample taking and sample preparation of bulk materials and suspensions of all kinds we are planning and produce sample taking and preparation plants tailor-made for your requirements.

Our product portfolio includes:

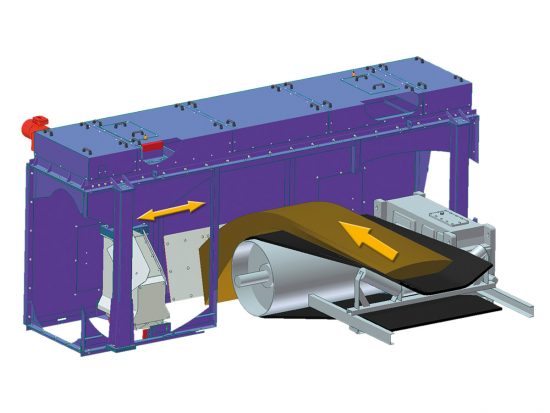

Representative sample taking from the moving product flow, e.g. from conveyor belts, from chutes and slides and from piping systems

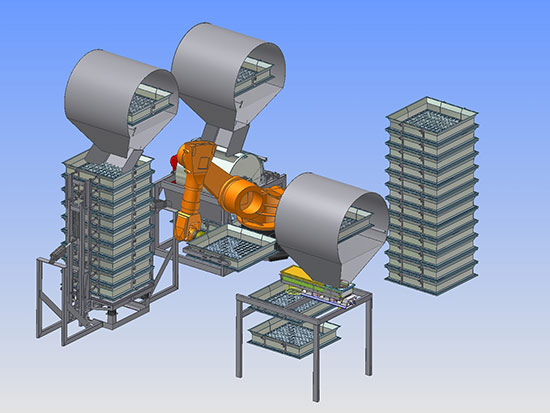

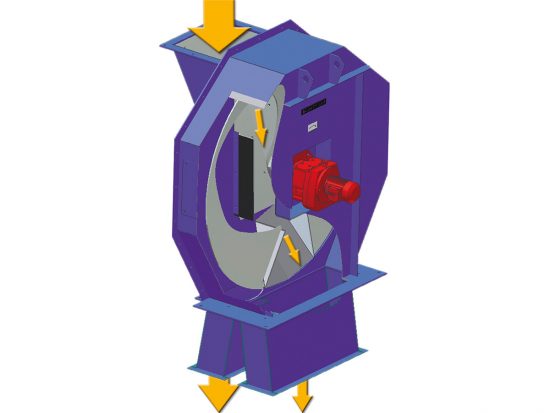

Fully automatic sample preparation by means of various crushers, mills and separating devices down into the micrometre range

Fully automatic sample transportation by air tube systems

Analysis of physical quantities like grain size, tumbler strength etc.

Chemical analysis, such as RFA / RDA, moisture, …

For each task SIEBTECHNIK can provide the appropriate solution or will create it jointly with you. Improve the precision of your analyses with our technology, because analysis commences with taking the sample.

SIEBTECHNIK machines are also operator friendly, uncomplicated in maintenance and, in particular, future-proof – thanks to our specialised service personnel and first-class spare and wear parts service, also for heritage machines.

Advantages of modern sample taking and sample preparation systems:

Regular extraction of laboratory samples, independently of weather or time, complying with the current ISO standards as the basis for reproducible and accurate product analytics

Representative automatic sample taking – without interrupting conveyance – from the moving material flow

Provision of retained samples, permitting repeated analysis in case of anomalies

Smoothing-out of material flow and grain size in by-pass flow of sample preparation plants for increasing the accuracy of online analysing devices

Reduction in work load for obtaining the sample material and improvement of work ergonomics by automated sample preparation

Improvement of safety at work because hazardous interventions of personnel into material flow are omitted and are replaced by automated sampling devices.