CONTURBEX screen scroll centrifuge

CONTURBEX screen scroll centrifuge

Universal machine for demanding tasks

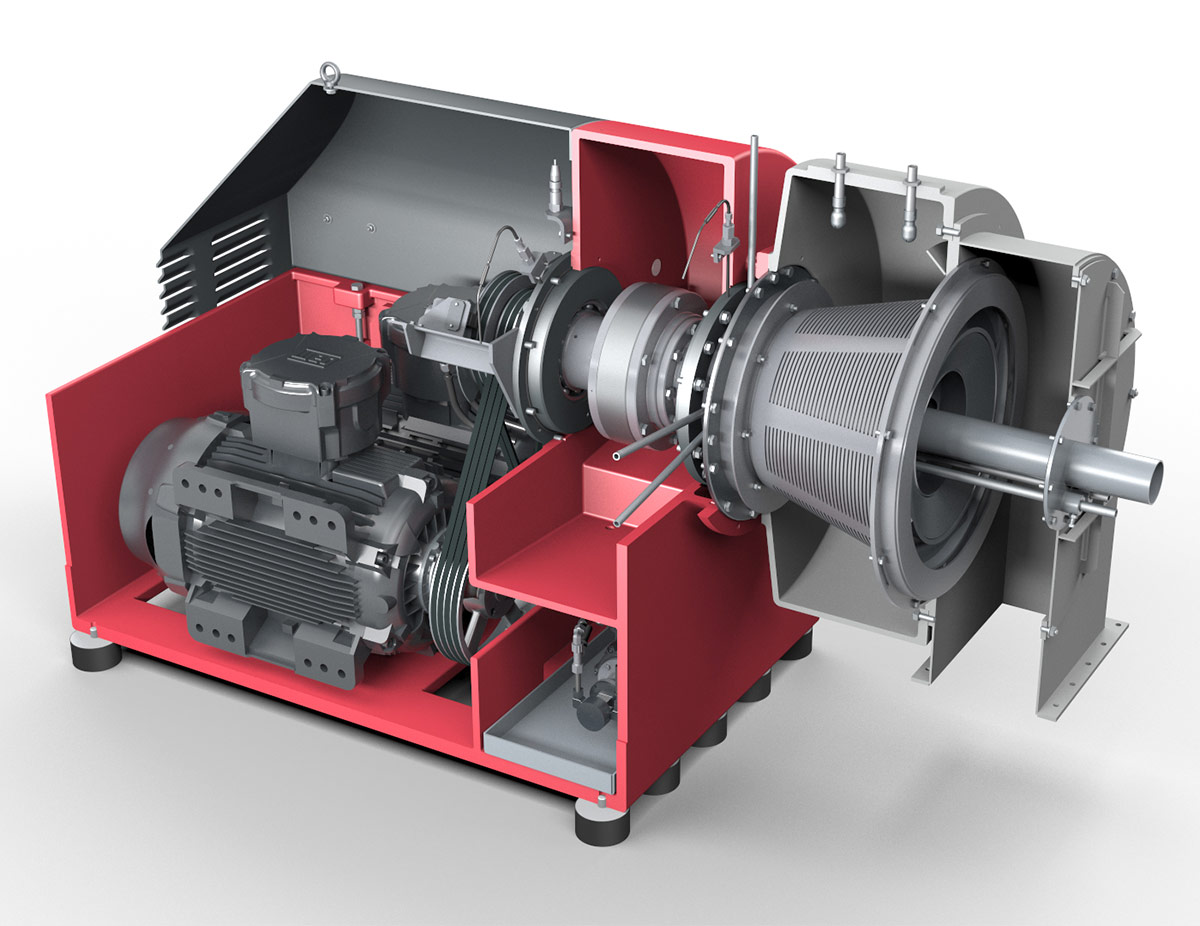

The SIEBTECHNIK TEMA CONTURBEX screen scroll centrifuge is a machine concept for demanding tasks that has been proving its worth for decades.

The CONTURBEX is a continuously operating filtration centrifuge for a broad range of applications. We achieve this flexibility by means of a centrifuge scroll driven at a differential speed.

There are thousands of CONTURBEX screen scroll centrifuges in operation in the most varied industrial sectors worldwide. They perform tasks in the chemical industry with specific corrosion-resistance requirements or gas-tight processes as well as fulfilling hygiene requirements in the food industry. We also offer versions of the CONTURBEX with USDA certification.

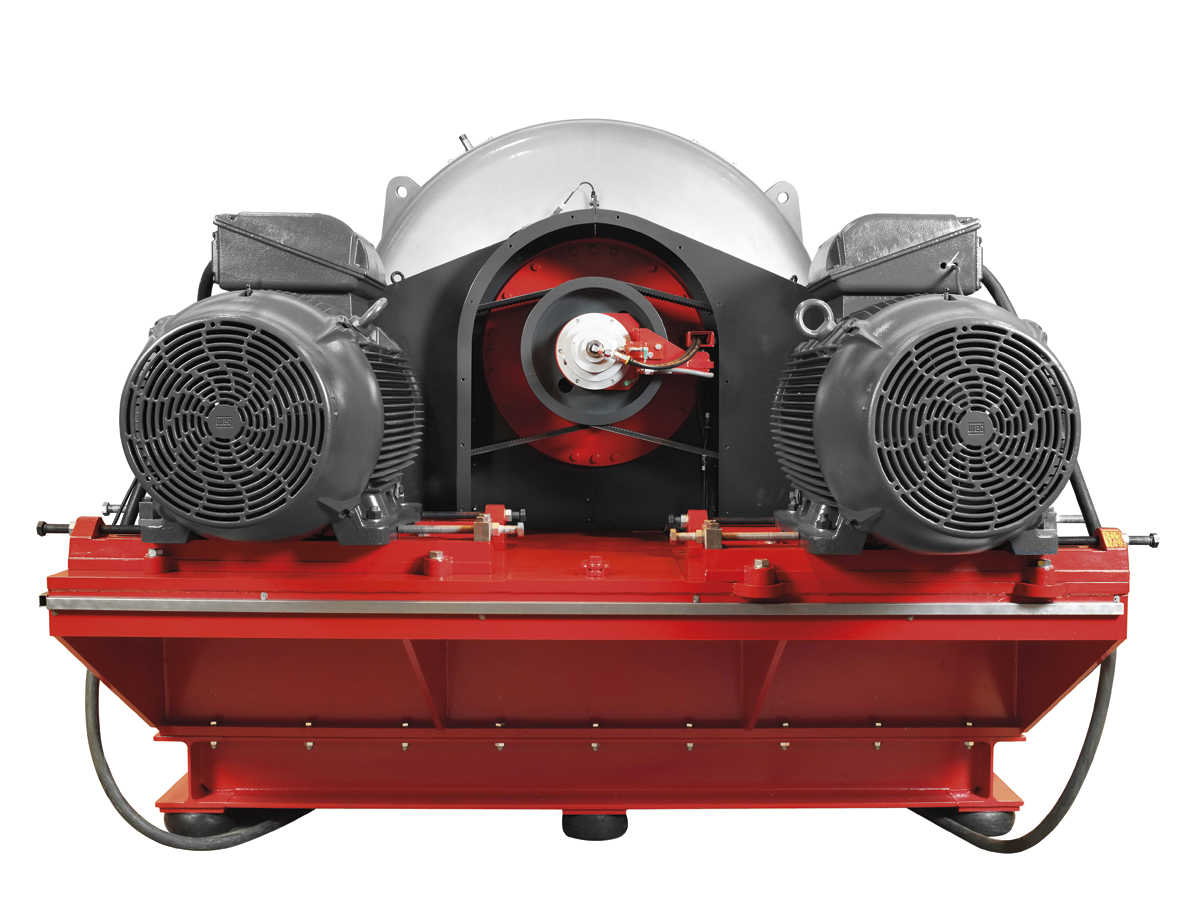

It was the increasingly demanding requirements, particularly for improved throughput rates, that motivated us to expand our CONTURBEX series. The CX type machine was developed with the aid of the latest design and production methods and on the basis of decades of experience.

The design principle simplifies maintenance and thanks to an optimum centre of gravity position guarantees a vibration-free and economically efficient operation with high throughput rates.

All CONTURBEX centrifuges have universal application and impress by their quiet running characteristics, even where feed conditions fluctuate.

Operational behaviour and mechanical characteristics

The centrifuge has the task of separating solid matter from suspensions. Here the screen scroll centrifuge impresses by its enormous range of applications, with both high and low feed concentrations.

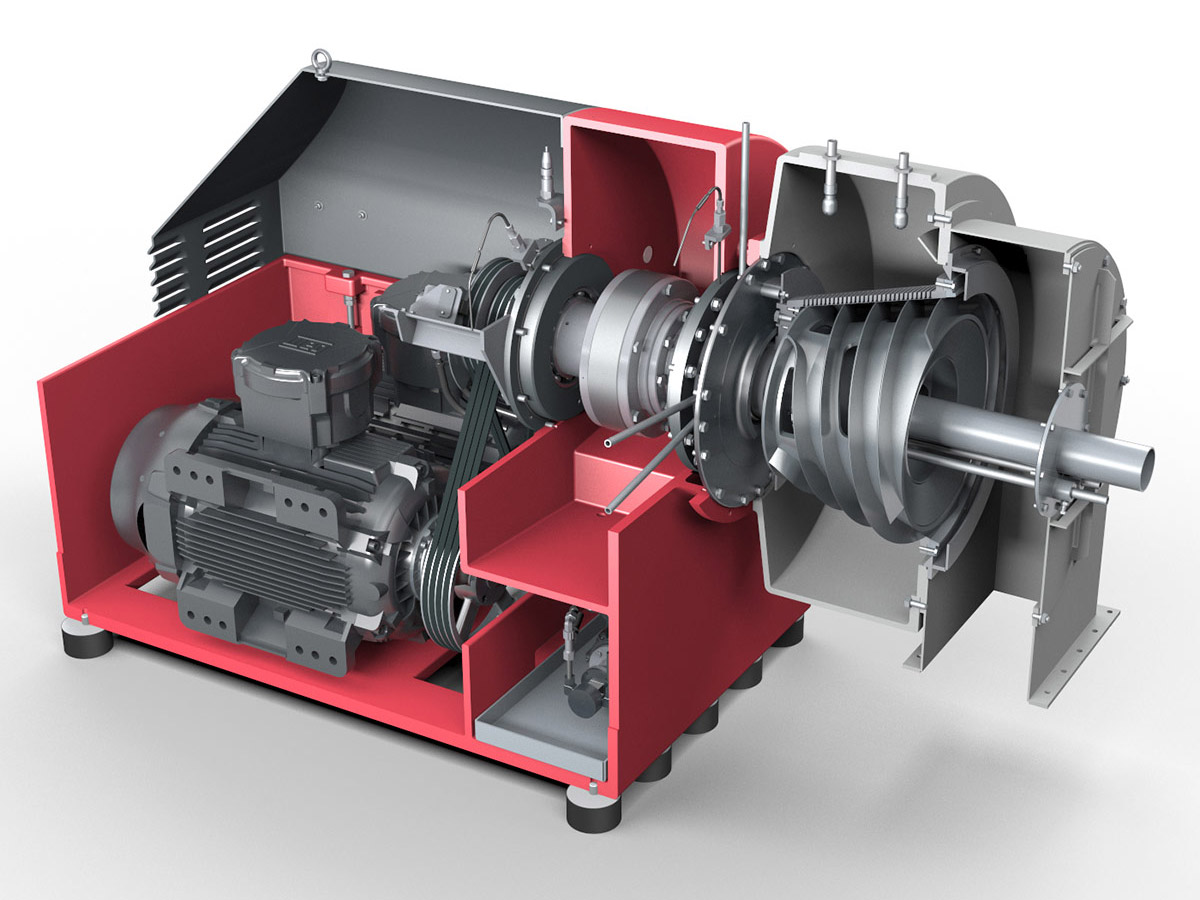

The unique functional principle of pre-accelerated suspension feed to the screening device, combined with homogeneous distribution by means of the scroll, enables this centrifuge to perform complex tasks.

We achieve optimum dewatering results by adapting the machine parameters, G force and dwell time.

The solid material is conveyed by means of a scroll rotating at a different speed from the bowl. Solid and liquid are conducted away into separate housing sections. Mother liquor and washing liquid can be drained away separately from each other.

The drive for the SIEBTECHNIK TEMA screen scroll centrifuge stands out for its powerful gear units and a high-quality bearing support. A central oil-circuit lubrication system supplies all the bearings with continuously filtered and temperature-controlled lubricant.

This machine concept enables excellent access to all the components coming into contact with the product. The result is fast servicing and maintenance procedures and special cleaning requirements to be met inside the process space.

Fitting variants

Because of the complex tasks there is a large number of different design variants available. The rotating components on SIEBTECHNIK TEMA CONTURBEX machines are available with different taper angles ranging from 0° to 20°.

A central component of this filtration centrifuge is the screening device. This is chosen to meet the specific requirements of the separating task.

The design of the worm is also a central consideration: the geometrical arrangement of the worm channels and the choice of suitable material or wear protection is decisive.

Taper angle of the rotating parts:

- 0° up to 20°

Screening devices:

- Slotted screens

- CONIDUR® screen plates

- Laser-perforated screen plates

- Water-blasted screen plates

- Punch-perforated plates

Drive design:

- Mechanical gear units (planetary/cycloid gear units)

- Hydraulic drives (self-regulating worm speed)

- Drives with adjustable speeds

- Drives with regulable speeds

Centrifuge housing seals:

- Open labyrinth seals

- Vapour-tight version

- Gas-tight version

- Explosion protected design in accordance with Directive 94/9/EC (ATEX 100a)

- Pressure-tight version with sliding ring seal

Material versions:

- Carbon steel

- Austenitic steels

- Duplex steels

- Hastelloy

- Titanium

Wear protection variants:

- Welded-on tungsten carbide material

- Ceramic

- Stellite special material

- Carbide metal

Housing designs:

- Equipment for product washing

- Pressure equalisation in air/gas flow circuit

- Separate drains for filtrate and washing liquid (dual cyclone)

- Solid ejection by discharge channel (race-track)

- Trace heating/cooling

- Insulation

- Suspension inlet or infeed worm

- CIP version

- Food-safe version to FDA/EU1935

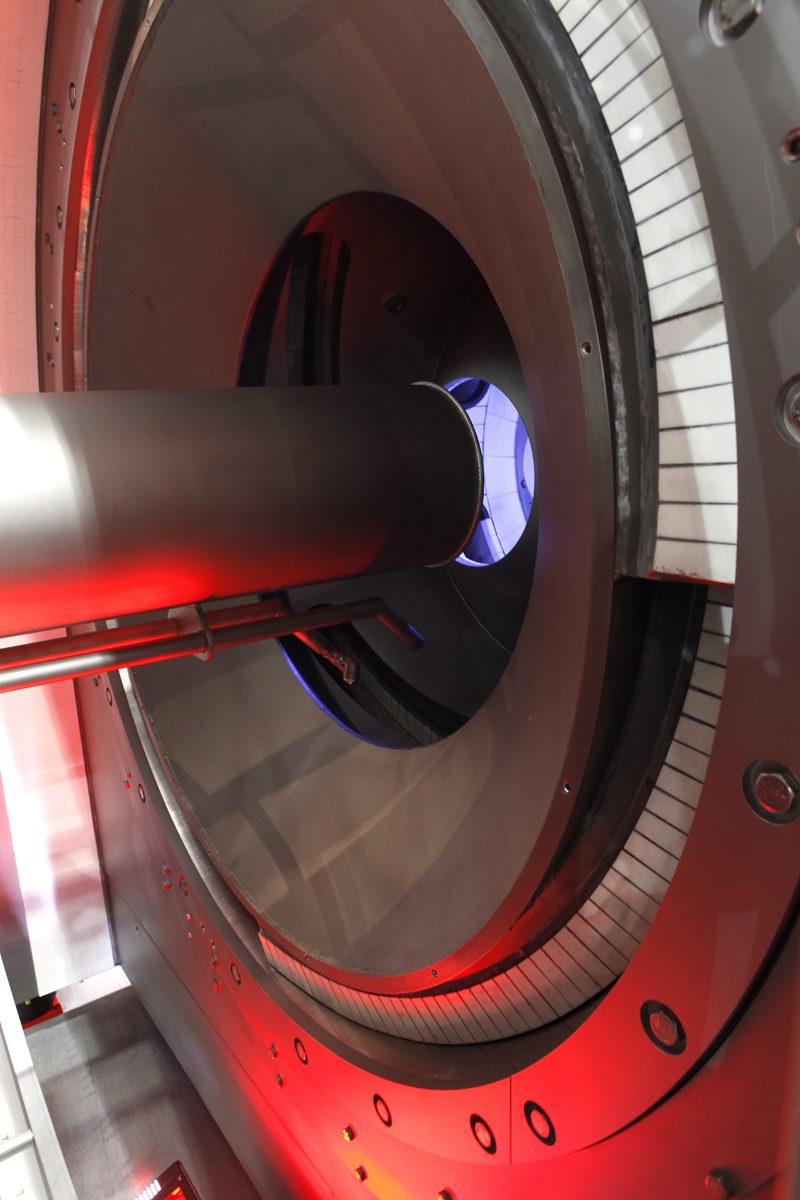

Drives for centrifuges

The solution to a separation task depends very decisively on the centrifuge drive. The centrifugal force required for solid-liquid separation is determined by the bowl or screen speed. To achieve the right speed for optimum separating results, it is frequently necessary to keep the speeds variable. The drive control needed for this is designed by our specialists specifically to fit your application.

Furthermore, on screen worm centrifuges and in decanters the speed differential between the solid-conveying worm and the bowl is decisive. It determines the time which the solid spends in the centrifuge and so the quality of the drying. The correct speed differential for your separation task is determined by the correct choice of gear unit. The speed differential here may be constant, but may also be variable. In the latter case the back-drive, where the otherwise fixed gear input shaft is also driven, is used. If the worm speed is required to be kept completely independent of the drum speed, hydraulic drives (viscotherms) or two-stage gear units with an upstream differential planetary stage are used.

To guarantee the operational reliability of your centrifuge, the drive system is continuously monitored. Excessive speeds, overcurrent and slip are identified and reported to the machine control system and there processed.

Only a drive system specially designed for your separating task will give optimum separating results.

Explosion protection / inertising

Explosion protection/inertising

Inertisation of our machines and systems may be necessary for various reasons. In many industrial processes it is necessary for safety reasons to reliably prevent the build-up of an explosive atmosphere through dust or gases (ATEX).

It may also be necessary to seal and overlay the product spaces with inert gas, e.g. nitrogen (N2) or carbon dioxide (CO2), to prevent oxidation and maintain product quality.

Use SIEBTECHNIK specialialists’ many decades of experience in all areas of industry to help seal and inertise the process spaces in your centrifuges.

We will be pleased to work with our customers to draw up an inertising concept for the integration of our machines into existing or scheduled plant systems.

Hygienic Design / CIP

The name SIEBTECHNIK is inseparably associated with dewatering tasks to meet the most stringent hygiene requirements. The separation of batter from frying oil at temperatures of approx. 200°C with the SHORTBOWL decanter centrifuge, the centrifuging of lactose crystals with the SHORTBOWL decanter centrifuge and the CONTURBEX screen worm centrifuge for the manufacture of baby food or the manufacture of extremely pure inorganic salts with our CONTURBEX and pusher centrifuges are some examples. Design features for this are the technical separation of the drive and processing sections of the centrifuge and highly developed sealing systems that are easy to clean by CIP.

For the optimisation of centrifuges in the hygiene sector and/or in areas where e.g. cross-contamination has to be prevented by CIP we use riboflavin tests to examine and optimise cleaning results.

Our self-developed and USDA-certified CIP nozzles, self-developed hygienic screw connections, special hygiene surfaces or our highly developed USDA-conformant sealing technology make many dewatering tasks possible only with our centriguges.

Service

Our reliable service enables optimum operation of your machines and systems. We offer energy optimisation, machine monitoring, an on-site maintenance and & repair service, OEM spare parts, damage cause analysis, maintenance & repair kits, stock inventory analysis, machine history management, personal technical consultation, training & workshops, 24 hr service, retrofitting & upgrades and used & loan machines.

Ask us, we’re there for you.

System solutions

SIEBTECHNIK TEMA has consistently developed itself into one of the world’s most innovative manufacturer of continuous centrifuges and suppliers of system solutions in the field of mechanical and thermal solid-liquid separation since the early 1940s. SIEBTECHNIK/TEMA is your reliable partner for customer-focused, custom-built machines and system solutions.

SIEBTECHNIK TEMA centrifuge and drier systems offer you the latest technology, customer- and product-specific special fittings and individual consultation at the pre-sales stage and reliable support in the after-sales process. For mechanical liquid separation continuously operating centrifuges are often the technically and economically best solution. They separate large volumes in closed housings with little space requirement and low energy and time costs. Also drying on the fluidised bed with fluidised bed driers and coolers has established itself in numerous branches of industry and applications.

Advantages

- Continuous operation

- Wide range of applications

- Very quiet running characteristics, even with fluctuating feed conditions

- Excellent product washing

- Low specific costs

- Advantageous design with shaft througholes on one side

- Proven suitability for hygienic applications

- Flexible drive concept

- High machine availability

- Minimum maintenance

- Long service life