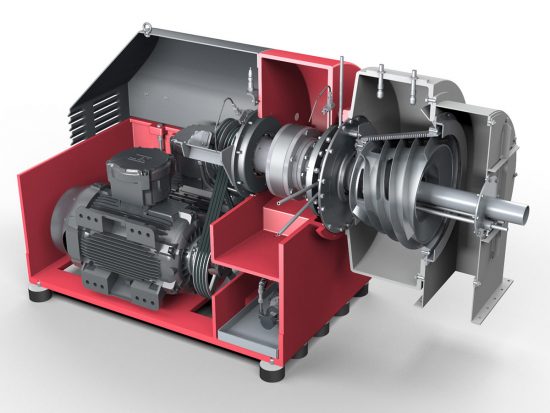

SHS pusher centrifuge

SHS pusher centrifuge

Application-focused to the last detail

The SIEBTECHNIK TEMA SHS pusher centrifuge has established and proved itself as a modern high-performance machine in many areas of industry. It reliably performs separation work in crystalline applications. SIEBTECHNIK TEMA is also one of the leading suppliers of pusher centrifuges for polymer products.

The basis for this success are individual design variants that perform complex separating tasks. All SIEBTECHNIK TEMA pusher centrifuges guarantee best results, amongst them low residual moisture, high solid yield and outstanding washing efficiency. Special attention is paid to the protection of the valuable solid particles. Especially in the areas of feed and discharge, where the product flow is accelerated and decelerated, SIEBTECHNIK offers individual solutions for every application.

We would be pleased to show you the possible applications of the SIEBTECHNIK TEMA SHS pusher centrifuge. Together with you we will find new solutions for your special separation task.

Operational behaviour and mechanical characteristics

The SHS shows its strengths particularly when meeting special process requirements: Long dwell times, little solids loss in the filtrate, low grain breakage/abrasion, intensive washing of solids cakes, wear minimisation.

These make it not only an outstanding separating unit for many crystalline products such as sodium or potassium chloride and sodium, ammonium or ferrous sulphate, but also the right solution to processing “exotic” products like granulate, seed, food, fibres, animal bone scrap and perhaps also your product.

The pusher centrifuge belongs to the continuously operating centrifuge group. The

solid is retained as a cake on a slotted screen basket and conveyed stepwise axially towards the solid discharge housing by an oscillating movement of the pusher panel. On the pusher centrifuge the transport speed of the solids cake is lower than e.g. on the screen worm centrifuge, while the dwell time for the centrifuged material in the bowl is correspondingly longer.

The size of the solids particles to be separated is preferably greater than 80 μm, although the thick, dense filter cake ensures an excellent yield, even of fine solids (natural filtration).

So both main features – the long dwell time and the dense filter cake – also enable efficient re-dewatering of solids with a large fine grain content which have been pre-dewatered in filters of all kinds.

For many applications the outer bowl is designed cylindrical-conical.

Because of this the difficult separation of capillary fluid from the corners between contacting grains is made considerably easier. The pusher energy needed for solids conveyance is also reduced.

The filling system (patent no. DE 195 46 019 C1) with acceleration cone and annular cup ensures extremely careful pre-acceleration and even distribution of the product. So, even where feed conditions are unfavourable, the mechanical loads on the machine, particularly wear, can be minimised.

An additionally integrated screening element, if required, enables product pre-thickening and so optimised filter cake formation.

The filtrate drain is generally designed to enable mother liquor and washing liquid to be drained off separately from each other.

Fitting variants

While there is a general trend towards standardisation, SIEBTECHNIK puts emphasis on detail. Our specialists devise and design the special machine for and often with the customer specifically for the product. This enables optimum efficiency to be achieved and individual requirements to be met.

For the most varied applications a range of centrifuge variants was consistently developed that enables specific applications to be very precisely provided for. For different throughputs there are up to 14 sizes with nominal bowl diameters of between 250 mm and 1200 mm to choose from.

SIEBTECHNIK pusher centrifuges are built with a one- to four-stage rotor, depending on the application and dewaterability of the product.

Depending on application, we manufacture all parts that come into contact with the centrifuged material from corrosion-resistant, austenitic steels, special bronzes, Hastelloy, nickel, titanium, etc.

With abrasive feed material we protect risk-exposed areas with wear-resistant materials and coatings.

Special versions

- Filling system with pre-dewatering (DBP)

- Product feed by means of filling worm

- Separate discharge/deaeration of mother liquor/washing liquid by means of

- double/multiple filtrate cyclone separator

- Gas-tight process space sealing

- Explosion-protected version conformant to Directive 94/9/EU (ATEX 100a)

- Food-safe version

- Further special versions on request

Drives for centrifuges

The solution to a separation task depends very decisively on the centrifuge drive. The centrifugal force required for solid-liquid separation is determined by the bowl or screen speed. To achieve the right speed for optimum separating results, it is frequently necessary to keep the speeds variable. The drive control needed for this is designed by our specialists specifically to fit your application.

Furthermore, on screen worm centrifuges and in decanters the speed differential between the solid-conveying worm and the bowl is decisive. It determines the time which the solid spends in the centrifuge and so the quality of the drying. The correct speed differential for your separation task is determined by the correct choice of gear unit. The speed differential here may be constant, but may also be variable. In the latter case the back-drive, where the otherwise fixed gear input shaft is also driven, is used. If the worm speed is required to be kept completely independent of the drum speed, hydraulic drives (viscotherms) or two-stage gear units with an upstream differential planetary stage are used.

To guarantee the operational reliability of your centrifuge, the drive system is continuously monitored. Excessive speeds, overcurrent and slip are identified and reported to the machine control system and there processed.

Only a drive system specially designed for your separating task will give optimum separating results.

Explosion protection / inertising

Explosion protection/inertising

Inertisation of our machines and systems may be necessary for various reasons. In many industrial processes it is necessary for safety reasons to reliably prevent the build-up of an explosive atmosphere through dust or gases (ATEX).

It may also be necessary to seal and overlay the product spaces with inert gas, e.g. nitrogen (N2) or carbon dioxide (CO2), to prevent oxidation and maintain product quality.

Use SIEBTECHNIK specialialists’ many decades of experience in all areas of industry to help seal and inertise the process spaces in your centrifuges.

We will be pleased to work with our customers to draw up an inertising concept for the integration of our machines into existing or scheduled plant systems.

Hygienic Design / CIP

The name SIEBTECHNIK is inseparably associated with dewatering tasks to meet the most stringent hygiene requirements. The separation of batter from frying oil at temperatures of approx. 200°C with the SHORTBOWL decanter centrifuge, the centrifuging of lactose crystals with the SHORTBOWL decanter centrifuge and the CONTURBEX screen worm centrifuge for the manufacture of baby food or the manufacture of extremely pure inorganic salts with our CONTURBEX and pusher centrifuges are some examples. Design features for this are the technical separation of the drive and processing sections of the centrifuge and highly developed sealing systems that are easy to clean by CIP.

For the optimisation of centrifuges in the hygiene sector and/or in areas where e.g. cross-contamination has to be prevented by CIP we use riboflavin tests to examine and optimise cleaning results.

Our self-developed and USDA-certified CIP nozzles, self-developed hygienic screw connections, special hygiene surfaces or our highly developed USDA-conformant sealing technology make many dewatering tasks possible only with our centriguges.

Service

Our reliable service enables optimum operation of your machines and systems. We offer energy optimisation, machine monitoring, an on-site maintenance and & repair service, OEM spare parts, damage cause analysis, maintenance & repair kits, stock inventory analysis, machine history management, personal technical consultation, training & workshops, 24 hr service, retrofitting & upgrades and used & loan machines.

Ask us, we’re there for you.

System solutions

SIEBTECHNIK TEMA has consistently developed itself into one of the world’s most innovative manufacturer of continuous centrifuges and suppliers of system solutions in the field of mechanical and thermal solid-liquid separation since the early 1940s. SIEBTECHNIK/TEMA is your reliable partner for customer-focused, custom-built machines and system solutions.

SIEBTECHNIK TEMA centrifuge and drier systems offer you the latest technology, customer- and product-specific special fittings and individual consultation at the pre-sales stage and reliable support in the after-sales process. For mechanical liquid separation continuously operating centrifuges are often the technically and economically best solution. They separate large volumes in closed housings with little space requirement and low energy and time costs. Also drying on the fluidised bed with fluidised bed driers and coolers has established itself in numerous branches of industry and applications.

Advantages

- Continuous operation

- Optimum product washing

- High solid yield

- Low specific costs

- Multi-stage rotor designs

- Product feed and pre-dewatering

(Patent no. 195 46 019 C1) - High machine availability

- Minimum maintenance

- Long service life